A Meditation on the Humble, Essential Food-Grade PE Glove

There is a quiet ballet that happens in kitchens everywhere—the sizzle of a pan, the rhythmic chop of a knife, the gentle fold of ingredients. It’s a dance of creation, of nourishment. And in this dance, there is an often-unseen guardian: the simple, transparent, food-grade disposable glove. At Xiamen Lidi Plastic Co., Ltd., we have dedicated ourselves to the art and science of this guardian. We believe that a food-grade disposable PE glove is more than just a piece of plastic; it is a promise. A promise of purity, a commitment to safety, and a fundamental tool in the modern creed of hygiene. It is a product that should perform its duty flawlessly and then recede into the background, its job done, its integrity unquestioned.

Part 1: The Blueprint of Purity - Our Specifications and Certifications

The journey of a truly trustworthy disposable PE glove begins not on the production line, but in the realm of science, standards, and unwavering specifications. We start with a foundation of integrity, because the hand that touches food touches health.

Our primary material is always virgin polyethylene resin. This is a critical choice. Unlike recycled materials, which can carry a history of contaminants and inconsistencies, our virgin PE resin is pristine, a blank slate that ensures a clean, predictable, and safe product from its very origin. This commitment to purity is what allows our gloves to meet and exceed stringent international food safety standards. Our products are certified to comply with FDA (Food and Drug Administration) regulations under CFR Title 21, meaning they are approved for direct contact with food, posing no risk of chemical migration or contamination.

But we go further. Our manufacturing facilities operate under the rigorous framework of the ISO 9001 Quality Management System. This isn't just a certificate on the wall; it is the DNA of our operation. It means that every batch of our food-safe polyethylene gloves is produced under a system of documented procedures, continuous monitoring, and traceability. From the moment the raw resin pellets enter our silos to the moment the finished gloves are packaged, every step is controlled, recorded, and auditable.

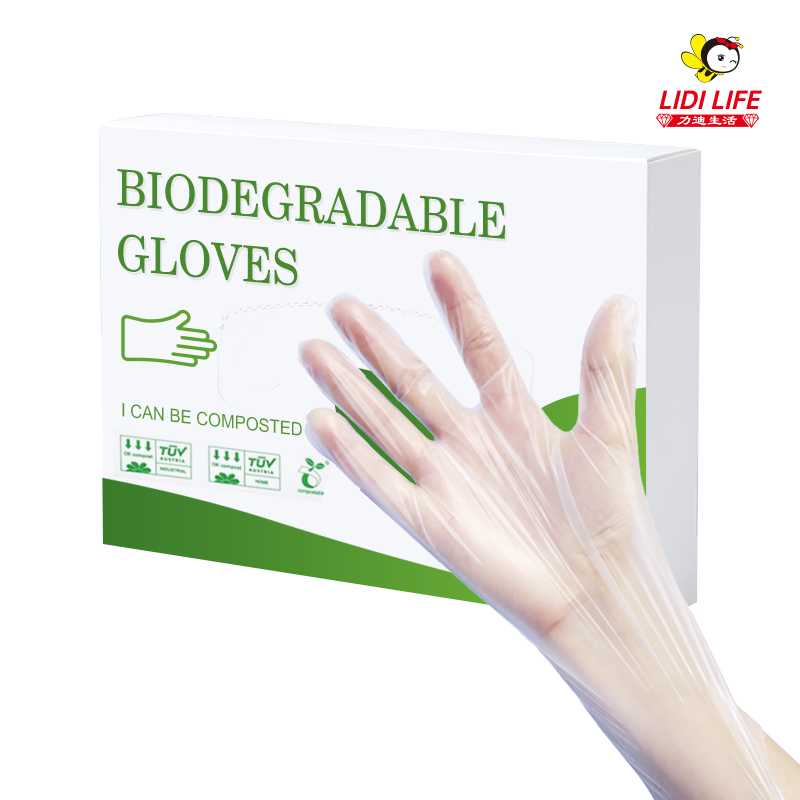

The physical glove specifications are meticulously calibrated. The thickness, typically ranging from 0.35 to 0.5 mils, is engineered in a "Goldilocks zone"—it's thick enough to provide a reliable, leak-resistant barrier against moisture and light oils, yet thin enough to remain incredibly lightweight and flexible, preserving the natural dexterity of the wearer's hand. We offer a full range of sizes, from Small to Extra-Large, because a proper fit is not a luxury; it is a necessity for both comfort and safety, preventing the glove from slipping off or tearing due to excessive tension.

Part 2: The Symphony of Subtlety - Our Product Highlights

A great product is defined not by one grand feature, but by a symphony of small, thoughtful details that, together, create an experience of seamless efficiency. We have obsessed over every facet of our disposable polyethylene gloves to elevate them from a simple commodity to a superior tool.

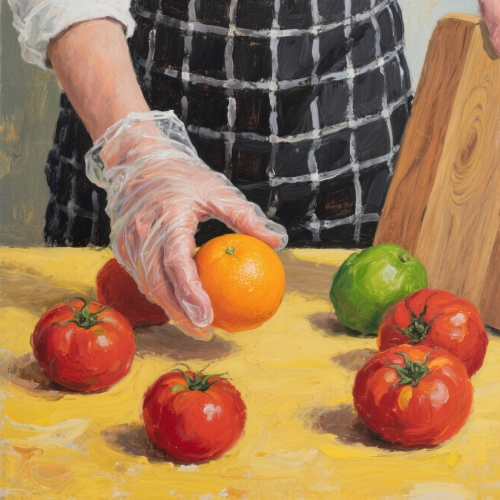

Consider the ambidextrous design. In the fast-paced environment of a commercial kitchen or a busy food stall, there is no time to fumble for a "right" or "left" glove. Our universal fit makes donning quick, intuitive, and efficient, a small but profound courtesy that saves precious seconds during a rush. Then there is the soft, textured finish. The surface of our gloves is lightly embossed, not just to prevent them from sticking together in the roll, but to provide a remarkably secure, non-slip grip. Whether you're handling a slick fish fillet, a greasy piece of chicken, or a wet vegetable, the glove provides confidence, reducing the risk of dropped items and wasted food.

A cornerstone of our design is the 100% powder-free guarantee. Many gloves use cornstarch or other powders to make them easier to don, but this powder can contaminate food, alter tastes, and for some individuals, cause irritation. Our powder-free gloves are donned smoothly and leave no residue, ensuring that the only thing that touches the food is the pure, clean glove itself.

The elastic cuff is another unsung hero. It’s not just a folded edge; it’s an engineered feature that provides a snug fit around the wrist, preventing the glove from rolling down during use and offering a more secure barrier that protects the wearer's sleeves. Furthermore, the crystal-clear transparency of our gloves is a feature in itself. It allows for visual inspection—a manager can see that gloves are being worn, and a worker can easily check for any potential, though rare, compromise in the glove's integrity. These are the hallmarks of a Lidi Plastic food glove—a product where every detail has been considered for performance, not just presentation.

Part 3: The Ripple of Benefits - The Multifaceted Advantages of Choosing Lidi

Choosing the right food handling gloves creates a ripple effect of benefits that extend from the individual user to the entire business and its customers. The advantages are foundational to operational excellence and brand trust.

The most critical advantage is, unequivocally, enhanced food safety. Our gloves act as a single-use, impermeable barrier between the handler's hands and the food. This is the first and most effective line of defense against cross-contamination prevention. It stops the transfer of bacteria, viruses, and allergens from hands to food, protecting the consumer and upholding the highest standards of public health. This is non-negotiable in today's world.

From a business perspective, the advantage is one of profound cost-effectiveness. Our disposable PE gloves offer an unparalleled balance of performance and price. They provide essential protection at a cost that makes frequent changes—as recommended by food safety protocols—financially sustainable. This economic efficiency for businesses allows for strict adherence to hygiene policies without straining the budget, making them an ideal choice for high-volume environments from catering companies to school cafeterias.

For the user, the advantage is comfort and convenience. The lightweight nature of our polyethylene food gloves means they do not cause the hand fatigue associated with heavier, more restrictive gloves. Their breathable nature reduces sweat and discomfort, making them more pleasant to wear for extended periods. This, in turn, encourages compliance with hygiene policies. When gloves are comfortable, people are more likely to wear them consistently and correctly. This simple fact makes our gloves a powerful tool for fostering a robust culture of hygiene and compliance within any food-handling organization.

Part 4: A Day in the Life - The Versatile Application Scenarios

The utility of our high-quality PE gloves extends far beyond the four walls of a restaurant kitchen. They are versatile guardians of hygiene in a multitude of settings, proving their worth wherever purity and protection are paramount.

The most evident application is in the professional food service industry. Here, our gloves are indispensable. They are used by line cooks handling ready-to-eat ingredients, by sushi chefs crafting delicate rolls, by bartenders garnishing cocktails, and by servers at buffet stations. They are the silent standard in bakery and pastry preparation, ensuring that delicate confections are touched only by pristine, food-safe surfaces.

But the story continues. In the food processing and packaging sector, our gloves are used on production lines for sorting, packing, and inspecting fruits, vegetables, and other food products. In the realm of catering and event services, they are essential for the off-site preparation and serving of meals, maintaining safety standards outside a controlled kitchen environment.

Their use also gracefully extends into the home kitchen. The modern home cook uses them for handling raw meats to prevent cross-contamination, for mixing marinades by hand, or for preparing meals for a family member with a compromised immune system. Furthermore, they find purpose in non-food industrial applications that still demand cleanliness and protection, such as in light electronics assembly, laboratory sample handling, or salon use, where their hypoallergenic and powder-free nature is a significant benefit. This incredible versatility of disposable gloves makes them a ubiquitous and essential tool across a wide spectrum of daily life.

Part 5: The Unwavering Standard - Our Rigorous Quality Control

The confidence you place in every single Lidi glove is not born of chance; it is the direct result of a multi-layered, relentless quality control process that functions as an unwavering standard throughout our production.

Our commitment begins with stringent raw material inspection. Every shipment of polyethylene resin is subjected to a battery of tests upon arrival. We verify its grade, purity, and consistency, ensuring it meets our strict specifications before it ever enters the production cycle. We build our reputation on this foundation of verified quality.

The manufacturing process itself is under constant surveillance through advanced production monitoring. Our state-of-the-art blown-film extrusion lines are equipped with sensors and laser gauges that continuously measure the film's thickness in real-time, ensuring millimeter-perfect consistency across every square inch of the glove. This is crucial for achieving the perfect balance of strength and flexibility.

However, technology is only one part of the equation. Our dedicated Quality Assurance team performs scheduled and random audits at every stage. They are the human guardians of our quality, conducting hands-on tests that machines cannot replicate. This includes regular tensile strength and leak tests, where sample gloves are subjected to stress and water to verify their integrity under conditions that far exceed normal use. We believe in testing to failure in our lab so that you never experience failure in yours.

Every single production batch is assigned a unique lot number, ensuring complete traceability from production to packaging. This means that should any question ever arise, we can instantly trace it back to its specific production date, line, and raw material batch. This closed-loop system of checks, audits, and documentation is what allows us to stand proudly behind our claim of producing some of the most reliable food-grade gloves on the market. Your trust is the cornerstone of our business, and we protect it with this unwavering, systematic discipline.

Part 6: Your Partner in Protection - Our Pre-Sales and After-Sales Service

At Xiamen Lidi Plastic, we view our relationship with clients not as a series of transactions, but as partnerships. We are not merely a manufacturer; we are your ally in ensuring safety, efficiency, and success in your operations.

Our pre-sales customer consultation is the bedrock of this partnership. We don't just take orders; we listen. We seek to understand your unique operational flow, your volume requirements, and your specific challenges. Our experienced team provides expert product guidance, helping you select the right glove thickness, size mix, and packaging format to best suit your needs. We strongly encourage potential partners to request free glove samples. We are confident that feeling the texture, testing the fit, and experiencing the tear-perforation firsthand is the most powerful testament to the quality we offer.

Understanding the importance of branding, we pride ourselves on our custom packaging solutions. We offer comprehensive OEM and ODM services, working closely with you to create bespoke packaging—from simple logo printing on individual glove bundles to fully customized dispenser box designs—that seamlessly integrates our product into your brand identity.

Once our partnership begins, our commitment deepens with a robust after-sales support system. You will have a dedicated account manager who ensures clear, consistent, and proactive communication. We provide efficient logistics coordination, managing the complexities of domestic and international shipping to ensure your supply chain remains uninterrupted and your inventory arrives on time and in perfect condition. We view every piece of feedback not as a complaint, but as a valuable insight that helps us grow and improve together.

In essence, we provide more than just boxes of gloves; we provide reliability, partnership, and a shared commitment to elevating standards of hygiene and safety. From the first inquiry to a long-standing collaboration, we strive to make your experience with Lidi Plastic as dependable and high-quality as the products we create.

Conclusion: A Simple Tool, A Profound Impact

As the dinner service winds down and the last pan is cleaned, the final act is often the soft snap of a glove being removed and discarded. It is a small, almost silent conclusion to the day's work. But within that simple action lies a profound truth: a commitment to care, a respect for health, and a dedication to a standard that often goes unseen, but is always present.

Here at Xiamen Lidi Plastic, we are honored to be a part of that commitment. We pour our expertise, our technology, and our unwavering dedication into creating a product that stands as a silent guardian in countless moments of creation and service. We believe that by perfecting this simple tool—ensuring its purity, its strength, its reliability—we contribute to a world where trust is built into the smallest of details.

Thank you for considering our products. Thank you for your own commitment to safety and excellence. Together, one glove at a time, we can help build a cleaner, safer, and more trustworthy world.

Alina Chan

Whatsapp/Wechat: 0086-13696918449

Email: alina@xmlidi.com