In today’s fast-paced world, Food Preservation Bags have become an essential tool in home kitchens, the food service industry, and even food processing. Whether storing leftovers, portioning ingredients, or transporting perishables, high-quality preservation bags effectively block air, prevent odor transfer, and extend food freshness.

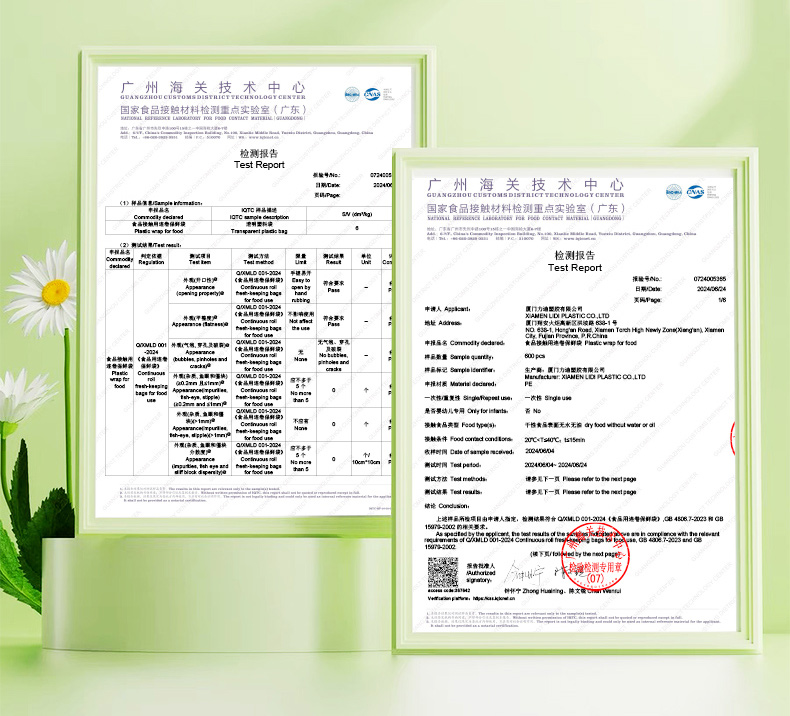

As a professional manufacturer of Food Preservation Bags (with over 30,000 sqm of workshop space, 400+ automated production lines, and 200+ workers), we hold international certifications including ISO 9001, ISO 14001, ISO 45001, BRCGS, and SGS audits. Our products are globally distributed, with long-term partnerships with McDonald’s, METRO, Nayuki, Burger King, Hengan Group, and more, ensuring every Food Preservation Bag meets high standards for diverse needs.

1. Key Advantages of Food Preservation Bags

The core functions of Food Preservation Bags are freshness locking, leak-proofing, and convenience. Our bags use food-grade PE/PP materials, non-toxic and odorless, complying with global food safety standards for refrigeration, freezing, vacuum sealing, and beyond.

Superior Seal: Precision heat-sealing technology ensures airtight closure, preventing moisture loss and bacterial contamination.

Puncture Resistance: Reinforced material withstands sharp items (e.g., bones, nuts).

Transparency: Clear visibility for quick content identification.

Eco-Friendly Options: Some lines use PLA biodegradable materials to reduce environmental impact.

2. Versatile Applications of Food Preservation Bags

(1) Home Kitchen: Smarter Food Management

Organization: Sort vegetables, meats, and seafood in different-sized bags to avoid cross-contamination.

Freezer Storage: Seal and freeze to prevent dehydration or freezer burn.

Travel-Friendly: Ideal for picnics or camping to carry snacks and fruits hygienically.

(2) Food Service: Boosting Efficiency

Prep Work: Batch-pack pre-cut veggies or semi-finished goods to save time.

Delivery: Leak-proof design keeps sauces contained, enhancing customer satisfaction.

Bakery Packaging: Preserves bread and pastries from moisture and staleness.

(3) Food Industry: Extending Shelf Life

Vacuum Sealing: Combined with vacuum technology, significantly prolongs freshness for meats and seafood.

Cold Chain Logistics: Withstands -40°C to 80°C, ensuring quality during long-distance transport.

3. How to Choose High-Quality Food Preservation Bags?

Material: Opt for food-grade PE/PP; avoid bags with plasticizers.

Seal Test: Fill with water and invert to check for leaks.

Odor Check: Premium bags are odorless; low-quality ones may smell pungent.

Size Selection: Match bag size to usage (small for snacks, large for whole chickens/vegetables).

4. Green Trends: Reusable & Biodegradable Options

Aligned with global sustainability, we’ve developed reusable silicone bags and bio-based biodegradable Food Preservation Bags, reducing plastic waste without compromising performance.

Though small, Food Preservation Bags play a vital role in daily life. As an industry leader, we’ll continue innovating to deliver smarter, greener solutions. For custom collaborations, contact us today!

Contact us today:

Email: yasin@xmlidi.com

WhatsApp: yasinguzel