As an ISO 9001 & BRCGS certified source manufacturer, we operate the world’s most advanced automated

production complex for PE/CPE/TPE disposable gloves. With 20+ years supplying McDonald’s, Starbucks,

and Burger King, our gloves touch 50 million meals daily across 30+ countries.

Ⅰ. Why Global Giants Trust Our Gloves

▶️ Zero-Contamination Guarantee

• For McDonald’s: 180°C oil-resistant CPE gloves (0.015mm) with patented anti-slip dots

• For Starbucks: PE gloves passing 4-hour coffee oil immersion tests

• For Nayuki: TPE gloves certified biodegradable in 24 months

▶️ Industry-Leading Production Power

| Capacity | Conventional Factory | XX Super Factory |

|---|---|---|

| Daily Output | 3 million | 8 million+ |

| Order Response | 7 days | 48 hours |

| Defect Rate | 0.8% | 0.01% |

Ⅱ. Material Innovation Engine

A. PE Gloves Series

• *Ultra-Thin (0.006-0.01mm)*: HACCP-compliant for bakery/pastry handling

• Texture Grip: Diamond-pattern surface reduces 70% slippage risk

• FDA 21 CFR 177.1520 certified

B. CPE Gloves Series

• ArcticShield™ Formula: Maintains flexibility at -50°C (cold chain/frozen food)

• High Clarity: 95% light transmission for precision tasks

• Heavy metal-free: Passes EU 10/2011 & FDA migration tests

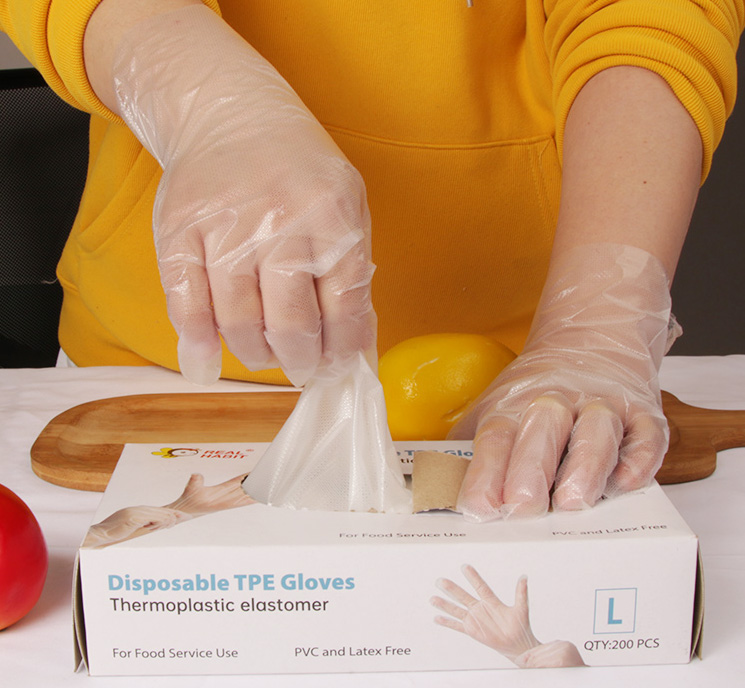

C. TPE Gloves Series

• EcoVolve™ Technology: 86% biodegradation in 2 years (third-party verified)

• Surgical-Grade Barrier: 0.028mm thickness blocks 99.99% bacteria (EN 374)

• 300% Elasticity: Tears only at 8N+ force (vs industry avg 5N)

Ⅲ. Beyond Standards: Our Quality Fortress

1. RAW MATERIALS - Food-grade polymer pellets (SGS audited) - Phthalate-free plasticizers - In-house lab: Daily heavy metal screening 2. PRODUCTION - Class 100,000 cleanrooms (ISO 14644) - AI vision inspection: 120 gloves/sec - 100% leak testing (ASTM F1671) 3. CERTIFICATIONS FSSC 22000 | ISO 13485 | BRCGS | Halal | Kosher | BSCI

Ⅳ. Client Victory Stories

▲ McDonald’s APAC: Reduced glove-related waste by 37% after switching to our 100% recyclable CPE gloves

▲ Nayuki’s Tea Master: “TPE gloves withstand 85°C tea brewing without odor transfer”

▲ Starbucks QA Team: “0 customer complaints about glove residue since 2020”

Ⅴ. Customization for Your Workflow

We engineer gloves for:

• High-fat food processing (anti-grease coating)

• Allergy

Conclusion: Your End-to-End Safety Partner

“We don’t just make gloves — we engineer trust for every meal.”

As the invisible guardian behind 50 million daily food servings

✓ Source factory efficiency (30% cost reduction vs. traders)

✓ Mission-critical reliability (0 recall incidents since 2005)

✓ Future-proof sustainability ( gloves degrade in 24 months)Contact us today:

Email: yasin@xmlidi.comWhatsApp: yasinguzel